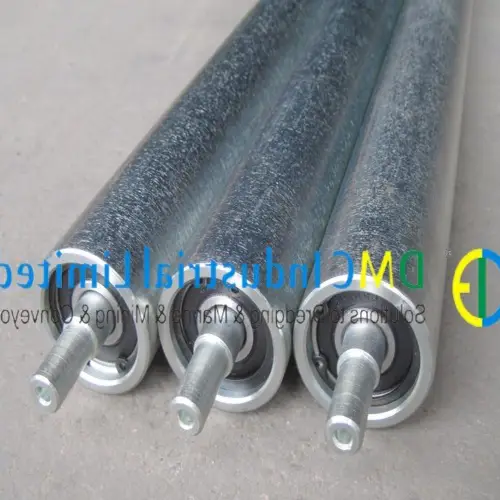

China Custom Hot Galvanized Heavy Duty Gravity Driven Roller Rubber Coated Drum Pulley

Product Description

The China Custom Hot Galvanized Heavy Duty Gravity Driven Roller Rubber Coated Drum Pulley is a high-quality conveyor roller used in various industries such as grand format digital printing, textile, paper mills, converting, films, laminating, packaging, plywood processing, foods, mining, and many others. It is designed to provide efficient and reliable conveying performance.

Customized Conveyor Roller (Conveyor Pulley, Gravity Roller/Power Roller/Driven Roller Pulley)

DMC Roller offers a wide range of rubber coated rollers, including Polyurethane (PU), Buna Nitrile rubber (NBR), Styrene Butadiene Rubber (SBR), CHINAMFG rubber, Silicon rubber, NR, and CR, among others. These rubber covered rollers are known for their durability and versatility, making them suitable for various conveyor applications.

With in-house processing capabilities, we can manufacture rubber covered rollers up to 6,000mm in length. For longer rollers, we also offer outsourcing options. Whether you require hot vulcanized or cold vulcanized rubber, we can meet your specific needs. Our rollers are designed to meet industry standards and can also be customized for friction and anti-static performance.

At DMC Roller, we are committed to delivering high-quality products. That’s why we provide inspection reports for every critical rubber coated roller, ensuring that our customers receive reliable and defect-free rollers for their conveyor systems.

Description:

| Production type | Custom OEM, ODM production conveyor (system), chain conveyor |

| Roller Material | SAE1571, 1045, S355J2H, Q345B, 38CrNiMo, 40Cr, Stainless steel 304L/316L, and aluminum 6063&6061T651, etc. |

| Types | Idler roller, drive roller, chain roller, tapered roller, free roller, logistics equipment roller for mine conveyor |

| Shapes | Flat roll, cambered or crowned roller pulley, anilox roll |

| Standards | Customized, CEMA, TD-2, JIS, ISO small rollers steel rolls manufacturing |

| Surface Coating | Paint, powder coating, zinc plating, rubber coated solid steel rolls cylinder for machine |

| Supply Capacity | >10,000pcs monthly complex roller logistics equipment, conveyor (system), chain conveyor |

| Assembly Service | Available conveyor idler trough roller precision grooved roller/grooving roller |

| Application Fields | Logistics equipment, belt conveyor systems, automotive, parcel & baggage handling system, ecommerce, warehouse & distribution conveyor solution, converting machine, mine conveyor, food industry, wood processing, etc. |

| Package | Plywood box (Fumigation-free) |

| Also Named as | Conveyor idler, idler conveyor roller, conveyor belt roller, carrying idler, rubber idler roller, conveyor idler roller, idler pulley, rubber conveyor pulley, drum pulley, belt drive pulley, drum roller, crowned pulley, transport roller, carrier roller, conveying roller, conveyor tail pulley, belt conveyor head pulley, rubber lagging drum pulley, impact roller, etc. |

| Other Products | Industrial steel roller, rubber coated roller, aluminum cylinder, machined components, welding, sheet metal fabrication |

Quality Control

– We accept SGS and any other third-party’s in-site inspection if necessary.

– Inspection reports are provided for each Critical to Quality (CTQ) and critical part before delivery.

– We confirm the Design for Manufacturability (DFM) with the customer before sample production.

– In case of quality issues, we provide 8D reports and Corrective Action Reports (CAR) to the client.

– We have regular maintenance schedules for all measuring tools.

– Strict controls and checkups are conducted on a regular basis.

– We pay attention not only to the parts themselves but also to material localization, production documentation, and packaging design for long-distance transportation.

Inspections

Quality runs through the entire process, from material selection to delivery. We provide inspection reports for each roller before shipment to ensure that our customers receive top-notch products. Below are sample reports for your reference.

Frequently Asked Questions (FAQs)

1. What industries can benefit from the China Custom Hot Galvanized Heavy Duty Gravity Driven Roller Rubber Coated Drum Pulley?

2. What materials are used for the roller coating?

3. Can the rubber covered rollers be customized for specific friction and anti-static requirements?

4. What standards are followed in the production of these rollers?

5. Are there any other products available from DMC Roller?

Performance Characteristics of Heavy Duty Pulley

Heavy duty pulleys are known for their exceptional performance characteristics. These features make them highly sought-after in various industries. Let’s explore the key points that make heavy duty pulleys stand out:

- Durability: Heavy duty pulleys are designed to withstand heavy loads and continuous use. Their sturdy construction ensures long-term reliability, even in demanding environments.

- High Load Capacity: These pulleys have a remarkable load capacity, allowing them to handle heavy objects with ease.

- Smooth Operation: Heavy duty pulleys are engineered to provide smooth and efficient operation, minimizing friction and ensuring optimal performance.

- Versatility: These pulleys can be used in a wide range of applications and industries, making them highly versatile and adaptable.

- Low Maintenance: Heavy duty pulleys require minimal maintenance, resulting in cost savings and increased productivity.

- Enhanced Safety: With features like secure locking mechanisms and reliable braking systems, heavy duty pulleys prioritize the safety of operators and equipment.

Types and Characteristics of Heavy Duty Pulley

There are various types of heavy duty pulleys, each with its own distinct characteristics. Let’s take a closer look at some common types:

- Single Groove Pulleys: These pulleys have a single groove and are suitable for applications where a single belt needs to be driven.

- Double Groove Pulleys: Double groove pulleys are designed to accommodate two belts and are commonly used in heavy machinery.

- V-Groove Pulleys: V-groove pulleys are shaped like a “V” and are ideal for applications that require superior belt gripping.

- Timing Belt Pulleys: These pulleys have specially designed teeth to ensure precise and synchronized movement.

Advantages of Heavy Duty Pulley Materials

The material used in the construction of heavy duty pulleys plays a crucial role in their performance. Here are the advantages of different materials:

- Steel Pulleys: Steel pulleys offer excellent strength and durability, making them suitable for heavy-duty applications.

- Aluminum Pulleys: Aluminum pulleys are lightweight yet strong, providing a balance between performance and weight.

- Plastic Pulleys: Plastic pulleys are corrosion-resistant and lightweight, making them ideal for applications where weight is a concern.

- Cast Iron Pulleys: Cast iron pulleys are known for their high load-bearing capacity and resistance to wear and tear.

Application of Heavy Duty Pulley

Heavy duty pulleys find extensive use in various industries, showcasing their value and importance. Let’s explore some of the key industries where these pulleys are widely employed:

- Automotive Industry: Heavy duty pulleys are crucial components in automotive systems, ensuring smooth power transmission.

- Emergency Services: These pulleys are utilized in emergency response equipment, enabling swift and efficient operations.

- Industrial Machinery: Heavy duty pulleys drive numerous industrial machines, contributing to their overall efficiency and productivity.

- Mining Industry: Mining equipment heavily relies on heavy duty pulleys for the extraction and transportation of minerals.

- Material Handling: Heavy duty pulleys are essential in material handling systems, facilitating the movement of goods and products.

Future Development and Opportunities

Heavy duty pulley products are expected to witness significant growth and present lucrative opportunities in the coming years. As industries continue to evolve and demand more efficient solutions, heavy duty pulleys are poised to meet these requirements. Some potential future developments and opportunities include:

- Improved Performance: Advancements in pulley design and materials will lead to enhanced performance and increased reliability.

- Technological Innovation: Integration of smart technologies and automation will further optimize the operation of heavy duty pulleys.

- Environmental Sustainability: Manufacturers will focus on developing eco-friendly pulley solutions to reduce environmental impact.

Choosing a Suitable Heavy Duty Pulley

When selecting a heavy duty pulley, it’s essential to consider several aspects to ensure the best fit for your specific requirements:

- Load Capacity: Determine the maximum load the pulley needs to handle to ensure it can withstand the intended workload.

- Material: Choose a pulley material that suits your application’s demands in terms of durability, weight, and resistance to environmental factors.

- Diameter and Size: Select a pulley with the appropriate diameter and size to ensure compatibility with other components and achieve optimal performance.

- Type of Pulley: Consider the specific type of pulley required based on the power transmission needs of your application.

- Bore Size: Ensure that the pulley’s bore size matches the shaft diameter to ensure a secure and efficient connection.

In conclusion, heavy duty pulleys are vital components in various industries, offering exceptional performance characteristics and versatility. Understanding their types, materials, and applications is crucial for making informed decisions when selecting the right pulley for specific requirements. The future holds promising opportunities for further advancements and innovations in heavy duty pulley technology.

Author: Dream